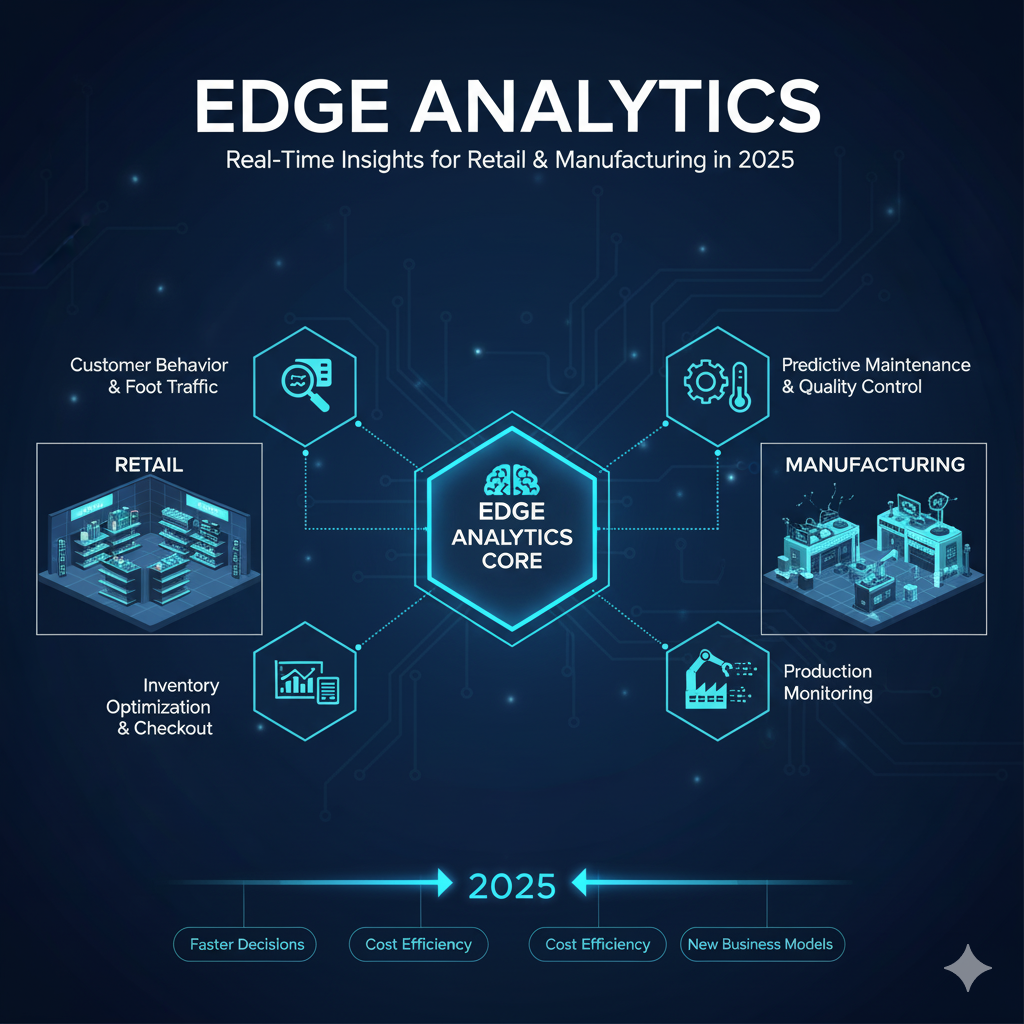

Edge Analytics: Real-Time Insights for Retail & Manufacturing in 2025

In today’s hyper-connected world, speed is everything. Businesses no longer have the luxury to wait for cloud systems to process data before making decisions. The future — and 2025 is proof — belongs to Edge Analytics, where data is analyzed right where it’s created.

From factory floors to retail stores, Edge Analytics empowers organizations to make real-time decisions, reduce latency, improve customer experience, and optimize operations — all without depending on centralized cloud processing.

But what exactly is Edge Analytics, and why is it becoming a game-changer for industries like retail and manufacturing? Let’s explore.

What Is Edge Analytics?

Edge Analytics refers to the practice of collecting, processing, and analyzing data at or near the data source (such as IoT sensors, cameras, or machines) rather than sending it to a centralized cloud or data center.

It’s a crucial component of Edge Computing, which enables faster, localized data insights for businesses that need real-time responses.

In simpler terms:

➡️ Cloud analytics = data analyzed after being sent to the cloud

➡️ Edge analytics = data analyzed instantly where it’s generated

📘 Learn more about these emerging technologies in our Data Analytics and AI Courses and Cloud Computing Courses at ChronoLearn.

Why Edge Analytics Matters in 2025 1. The Explosion of IoT Devices

According to Statista, there will be over 30 billion IoT-connected devices by 2025.

Each device generates massive data — from sensors in factories to cameras in retail stores. Sending all this data to the cloud is slow, expensive, and inefficient.

Edge Analytics processes this data locally, reducing bandwidth usage and improving speed.

2. Real-Time Decision-Making

In manufacturing, milliseconds can prevent equipment failure.

In retail, real-time insights can prevent inventory shortages or improve customer experience.

Edge analytics enables instant decision-making, which is mission-critical in 2025’s competitive environment.

3. Enhanced Privacy and Security

Since data doesn’t always travel to the cloud, Edge Analytics reduces exposure to cyber threats and helps companies meet privacy regulations like the GDPR and India’s DPDP Act (2023).

4. Cost Efficiency

By processing data locally, organizations cut down cloud storage and transmission costs — while still leveraging insights in real-time.

Edge Analytics in Retail: How It’s Transforming the Customer Experience 🛒 1. Predicting Customer Behavior in Real Time

Retailers like Walmart and Target use edge analytics to monitor customer movement and preferences in stores.

Using in-store sensors and cameras, they can adjust lighting, music, and promotions instantly based on foot traffic and demographics.

For example, Target uses shelf sensors and AI cameras to track which aisles attract the most attention and which products are picked up most frequently — enabling smarter merchandising decisions.

🛍️ 2. Smart Checkout & Queue Management

Edge-enabled cameras detect when checkout lines are forming and automatically alert staff to open new counters — reducing customer wait time.

Amazon Go stores are pioneers in this model, using edge processing and computer vision to enable “Just Walk Out” technology — no cashiers, no waiting.

📦 3. Real-Time Inventory Optimization

Edge Analytics allows retailers to track inventory levels across multiple locations without waiting for centralized systems.

For instance, Zara uses IoT-enabled shelves to track stock in real time, ensuring popular products are restocked automatically — improving both customer satisfaction and revenue.

👉 Dive deeper into retail analytics trends through our Business Analysis and Improvement Courses.

Edge Analytics in Manufacturing: From Reactive to Predictive Operations ⚙️ 1. Predictive Maintenance

One of the biggest breakthroughs of Edge Analytics is predictive maintenance — detecting issues before they cause downtime.

General Electric (GE) uses sensors on factory equipment to monitor vibration, temperature, and performance metrics in real time.

Their edge-based analytics identify early signs of equipment failure, reducing unplanned downtime by up to 30%.

🏭 2. Quality Control in Real Time

Instead of manually checking every product, edge-enabled cameras analyze quality in milliseconds.

Siemens leverages Edge AI to inspect thousands of parts per minute, immediately flagging defects — saving millions in recall and waste costs.

🔄 3. Supply Chain Resilience

In 2025, global manufacturing faces constant supply chain disruptions — from weather changes to geopolitical events.

Edge analytics systems now predict disruptions using real-time data from logistics sensors and reroute shipments automatically.

For example, Bosch uses IoT-driven analytics to monitor supplier performance, delivery routes, and raw material availability in real time — ensuring minimal production interruptions.

⚡ 4. Energy Optimization

With sustainability becoming a core KPI, manufacturers use edge analytics to monitor and optimize energy consumption across factories.

This approach helps achieve carbon-neutral operations, a major ESG goal in 2025.

Real-World Case Studies: Edge Analytics at Work

🔹 Case Study 1: Coca-Cola’s Smart Factories

Coca-Cola has integrated edge analytics into its bottling plants.

Using real-time machine sensors, Coca-Cola monitors water usage, pressure, and temperature across its factories.

As a result, they’ve cut energy waste by 15% and reduced maintenance costs significantly.

🔹 Case Study 2: Walmart’s Edge Retail Intelligence

Walmart uses edge servers within stores to process security camera feeds, heat maps, and checkout data locally.

This helps detect theft, optimize shelf placements, and personalize offers based on demographics — all without sending customer data to the cloud.

🔹 Case Study 3: Tata Steel (India)

Tata Steel employs Edge IoT systems for predictive maintenance in its Jamshedpur plant.

Their system monitors equipment like conveyors and furnaces in real-time, identifying faults instantly — resulting in 20% fewer production halts and a 15% cost reduction in maintenance.

🔹 Case Study 4: Adidas’ Speedfactories

Adidas set up smart factories in Germany and the U.S. with edge-based robotic systems.

The analytics at the edge help robots adapt instantly to material changes, improving product quality and reducing production cycles from months to days.

Edge Analytics and Cloud Analytics, though closely related, serve different purposes and environments. Edge Analytics processes data directly at or near the data source, such as sensors or local devices, allowing real-time decision-making with almost zero latency. This makes it ideal for time-sensitive industries like manufacturing, retail, healthcare, and energy, where immediate insights can prevent delays or equipment failures. Additionally, because data doesn’t need to travel to distant servers, bandwidth costs are significantly lower, and there’s a reduced risk of data exposure during transmission, enhancing overall security.

In contrast, Cloud Analytics processes data in centralized servers, making it more suitable for long-term reporting, trend analysis, and complex data storage. However, it can face challenges like higher latency and increased bandwidth costs, as large volumes of data must be transmitted to the cloud.

In practice, both models complement each other. Many modern organizations adopt hybrid architectures, where critical, time-sensitive decisions are made at the edge, while historical data and advanced analytics are handled in the cloud to achieve the best of both worlds.

Building an Edge Analytics Strategy: A Step-by-Step Framework Step 1: Define Your Objectives

Identify which business problems require instant insights — e.g., real-time quality control, inventory optimization, or machine health monitoring.

Step 2: Choose the Right Devices

Invest in IoT-enabled sensors, cameras, and industrial gateways that support edge processing.

Step 3: Select a Platform

Use modern edge platforms such as:

-

Azure IoT Edge

-

AWS IoT Greengrass

-

Cisco Edge Intelligence

Step 4: Integrate AI and ML Models

Deploy lightweight AI models that can run locally on devices to detect patterns and anomalies instantly.

Step 5: Connect with Cloud Systems

For historical data analysis and visualization, connect your edge systems with platforms like Power BI, Tableau, or Snowflake.

Step 6: Monitor, Improve, and Scale

Start with one pilot site and gradually expand as models mature. Use KPIs such as downtime reduction, energy savings, and customer satisfaction.

👉 Learn how to design such frameworks in our Advanced Cloud Computing and IoT Integration Courses.

Benefits of Edge Analytics for Businesses

-

Faster decision-making

-

Reduced operational costs

-

Improved equipment uptime

-

Enhanced data security

-

Lower cloud dependency

-

Increased sustainability and energy efficiency

According to Gartner, 70% of industrial IoT deployments will rely on edge analytics by 2025 — making it a must-have skill for professionals in data, IT, and operations.

Challenges and Considerations

While edge analytics offers enormous benefits, organizations must address a few challenges:

-

Hardware Costs – Edge devices require upfront investment.

-

Integration Complexity – Aligning with legacy systems can be difficult.

-

Skilled Workforce – Companies need professionals trained in AI, IoT, and Data Analytics.

-

Data Governance – Managing decentralized data securely remains a key priority.

💡 Future leaders can overcome these challenges through structured upskilling. Explore our AI & Data Analytics Professional Programs.

The Future of Edge Analytics in 2025 and Beyond

Edge Analytics will continue to evolve alongside 5G, AI, and digital twins.

Here’s what’s next:

-

Edge + Generative AI: Real-time predictive and prescriptive insights from edge-based models.

-

5G-Powered Edge Devices: Ultra-low latency for real-time industrial automation.

-

Edge-to-Cloud Collaboration: Hybrid frameworks allowing centralized learning and decentralized execution.

-

Sustainable Edge Operations: AI-driven optimization for carbon-neutral manufacturing.

By 2030, experts predict that over 75% of enterprise data will be processed at the edge (IDC Report).

Real-World Example: Reliance Retail (India)

Reliance Retail, one of India’s largest retail networks, is piloting edge analytics in select stores.

Their edge-enabled POS systems monitor real-time sales trends and customer patterns, allowing local managers to adjust pricing or promotions immediately.

This shift has led to a 12% increase in sales and improved customer satisfaction — a perfect example of how real-time data = real business results.

Final Thoughts

In 2025, Edge Analytics is not just a technology trend — it’s a strategic advantage.

As data grows exponentially, businesses that can analyze, act, and adapt instantly will dominate their industries.

From predicting customer needs in retail to maintaining machines in manufacturing, edge analytics is redefining how modern businesses make decisions.

If you want to learn how to implement Edge Analytics, IoT, and AI in business, explore our industry-ready training programs at ChronoLearn:

Empower your career — and your organization — with real-time data intelligence today.